Minimizing food waste during transportation is a critical challenge for delivery companies – ⅓ of the food produced globally goes to waste due to inadequate storage conditions and supply chain inefficiencies.

Telematics can help freight companies better deliver temperature-sensitive products to their retail destinations and reduce food loss during transportation. Read this article to find out how!

Products Requiring Special Care

First and foremost, let’s acknowledge the products that require special handling and a temperature-controlled environment. By definition, goods that are likely to deteriorate within a relatively short amount of time are referred to as perishables. Some of the most common ones are:

- Meat and poultry;

- Fish;

- Fruits and vegetables;

- Dairy products;

- Pharmaceuticals, etc.

As people like to eat a wide variety of non-seasonal foods, certain goods have to be transported over long distances. For example, in Eastern Europe, there is no production of tropical fruits whatsoever. Similarly, if a specific product is out of season in your country, it’s likely available somewhere else.

When transporting temperature-sensitive products, a specific temperature setting should be selected. In total, four temperature categories are among the most typical: deep freeze (-25°C to -30°C), frozen (-10°C to -20°C), chill (2°C to 4°C) and near-room temperature (12°C to 14°C).

Failing to keep perishable goods at the correct temperatures can result in rejected loads, reputation damage and financial losses for your business.

This certainly applies to many local retailers, too.

Minimise Food Waste During Transportation

So, how can carriers keep perishables in excellent condition until they reach the consumer’s table? This is where telematics comes in handy.

When using road transportation, refrigerator trucks are the most suitable option for carrying perishable freight. However, cold chain trucks can’t guarantee 100% reliability as refrigeration units can simply break down or fail due to human error. And, even if the cargo is insured, you might find yourself paying out of your own pocket.

Tracking the reefer data and receiving timely notifications of any changes through an advanced cold chain monitoring solution can help avoid errors and issues. This way, you will receive verified metrics of any sudden temperature changes within your cargo and detect potential problems before they have an adverse effect.

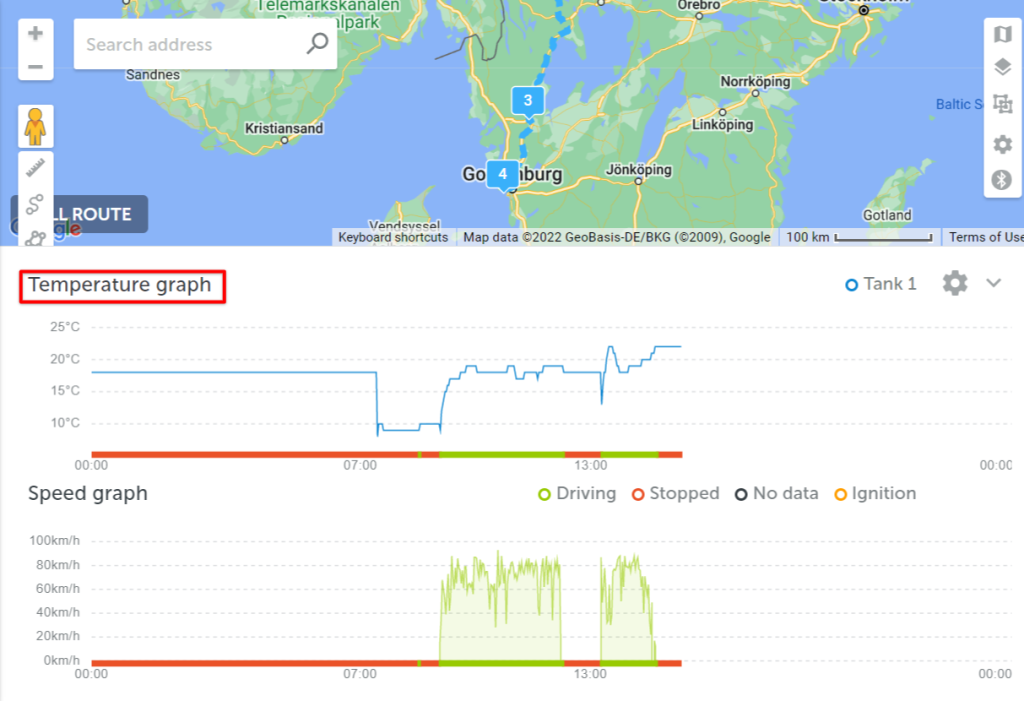

A temperature graph for a refrigerated trailer on the Mapon platform that displays fluctuating temperatures.

Why does it matter? Even the newest and most advanced technology requires maintenance, and refrigeration units are no exception. Staying informed allows you to deal with maintenance operations in a timely manner and avoid any food waste in transportation. Read more about the challenges and solutions of temperature monitoring in logistics in another blog article here!

Remote Monitoring of Cargo Temperatures

Whether you deliver frozen fish to a restaurant or milk to the local store, the right tools will help ensure that your product is kept at the proper temperature and limit food waste during transportation. Before all else, consider using temperature sensors that provide data on your reefer thermal conditions. Depending on the need, you can use either wired temperature sensors or temperature-measuring devices supported by Bluetooth technology.

To start gathering information from the temperature sensors located in your reefer, you’ll need a high-precision telemetry device that’s connected to the vehicle’s refrigeration unit. Later on, both dispatchers and fleet managers can remotely access unit data all on a single fleet management software.

What’s more, temperature monitoring works great when combined with real-time GPS tracking, as it’s vital to detect exactly where and when your cargo may be affected by temperature fluctuations. Similarly, the attached tracking device can help with monitoring the refrigeration unit battery status and engine hours.

Another practical way to use the Mapon temperature monitoring solution is by integrating data from the most popular temperature control system manufacturers such as Thermo King, Carrier, and Lumikko. This feature will provide an in-depth analysis of different parameters displaying reefer supply air temperature, return air temperature, and other data.

Employing such practices results not only in less food loss during transportation and more satisfied customers but also in efficient leadership.

For instance, Kreiss, one of the leading logistics companies in Europe, highly appreciates the advantages of the cold chain temperature monitoring solution. Since implementing it, the company has gained a clear competitive advantage and set new standards for refrigerated product shipping companies.

Food waste during transportation is a serious issue – despite the fact that the world produces more than enough food to feed everyone, around 800 million people go to bed on an empty stomach every night.

So, find ways how you can improve not only the situation in the world, but also your company’s operations. Contact our team for more information on our temperature monitoring solution!