Make sure temperature-sensitive products reach their destination fresh and safe for consumption. Use cold chain monitoring to transport perishables at the right temperature and eliminate the risk of human error.

Cold chain monitoring ensures that perishable items such as fruit, meat, and pharmaceuticals remain fresh throughout their journey and are safe for consumption.

Cold chain tracking helps you stay compliant with regulations that apply to the transportation of temperature-sensitive goods whether it's guidelines for pharmaceuticals or food safety regulations.

A remote reefer monitoring system lets you detect any temperature issues early on and take action. This way, you can prevent spoilage, minimise waste, and avoid financial losses.

You only need two devices to start using the cold chain tracking solution:

A Carrier Gateway, Thermo King iBox, or Thermo King Bluebox that is connected to the refrigeration unit.

The Mapon Expert device that transfers real-time data directly to the Mapon platform.

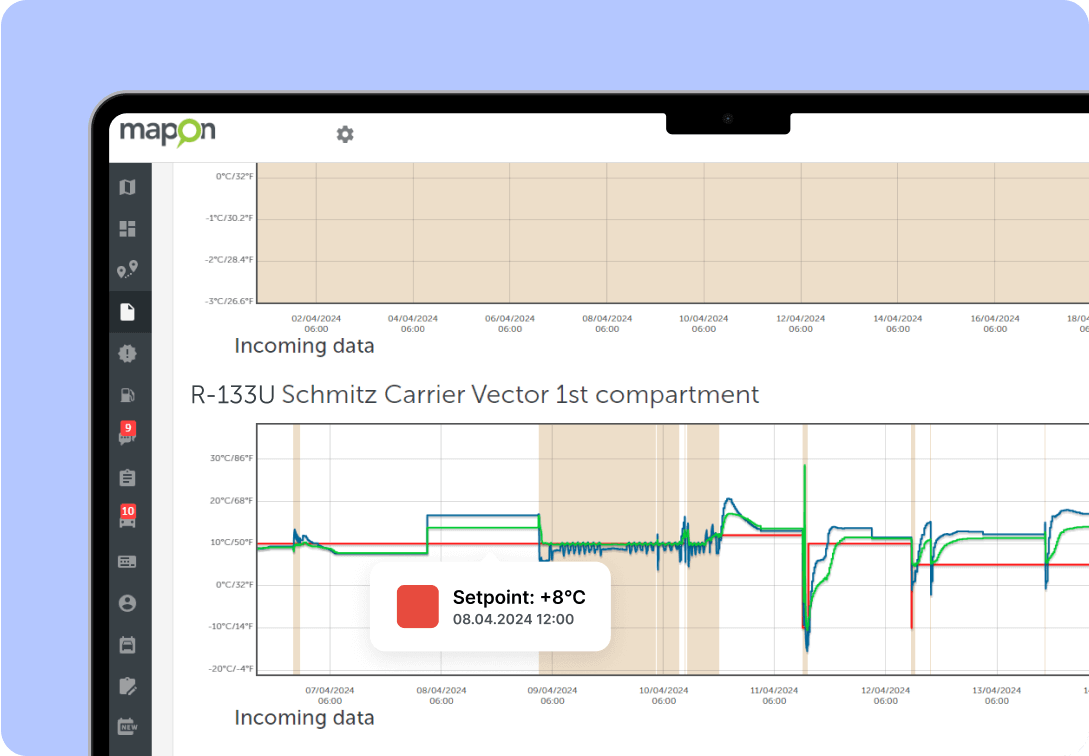

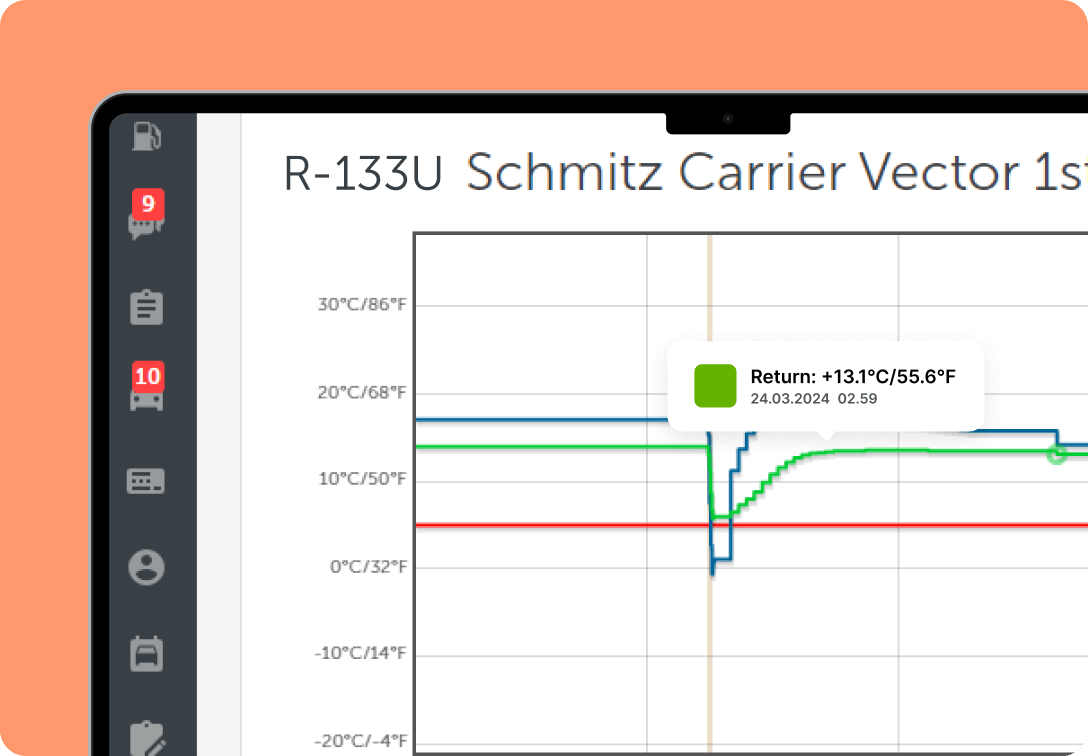

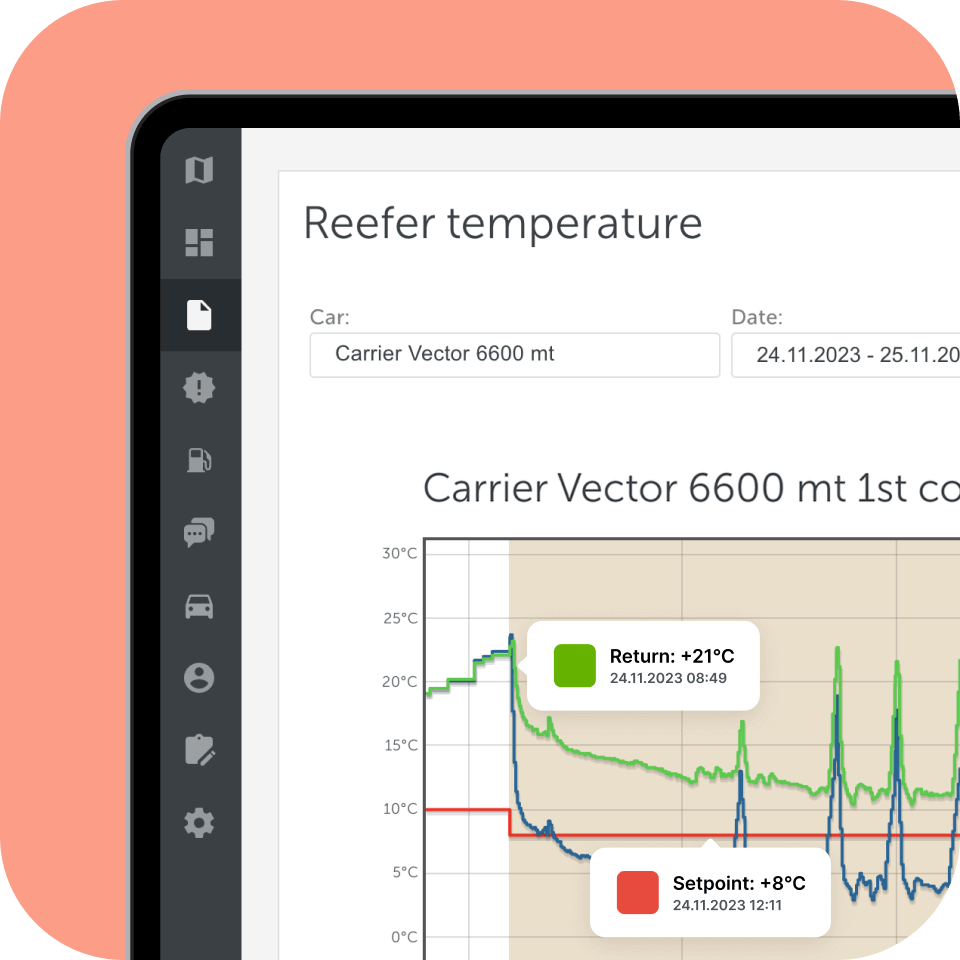

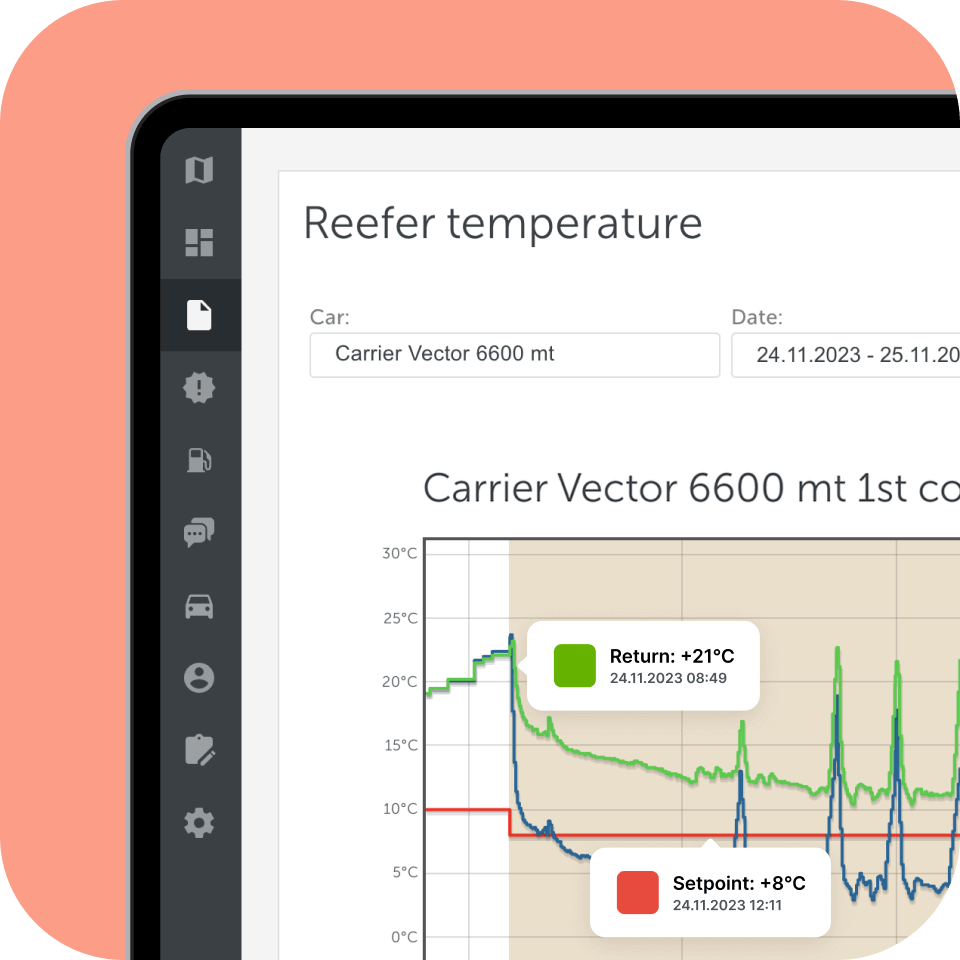

The days of big paper printouts are over. We turn temperature data into digital easy-to-understand graphs.

Follow the data in real time and adjust the displayed information using filters and zoom-in features to view specific data points.

You can also combine cold chain monitoring with the GPS tracking solution to see when and where the temperature changes happened.

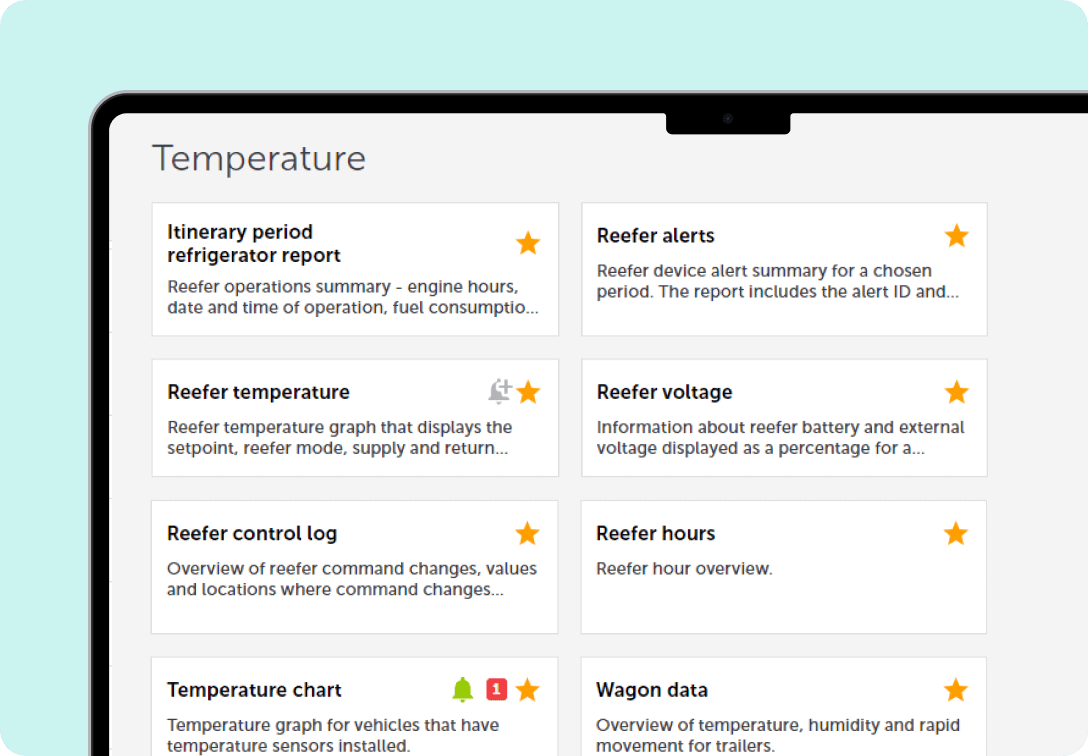

Here is what you can track with our remote reefer monitoring system:

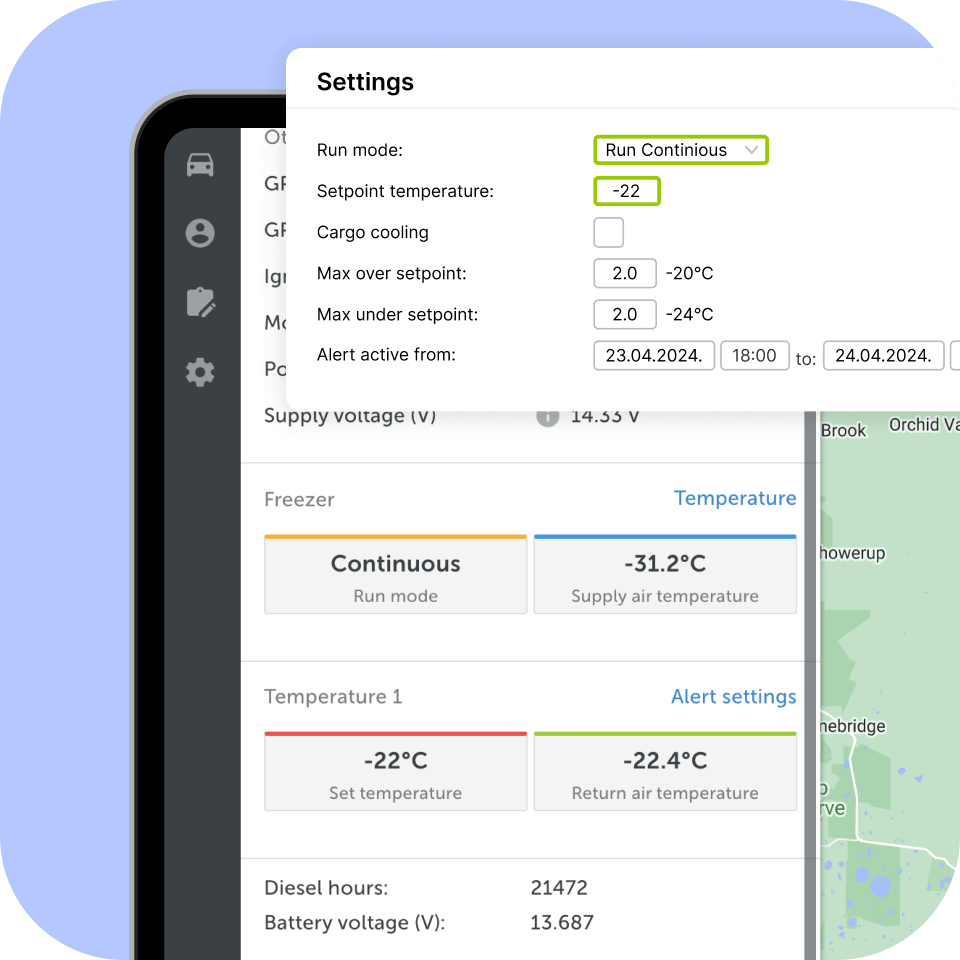

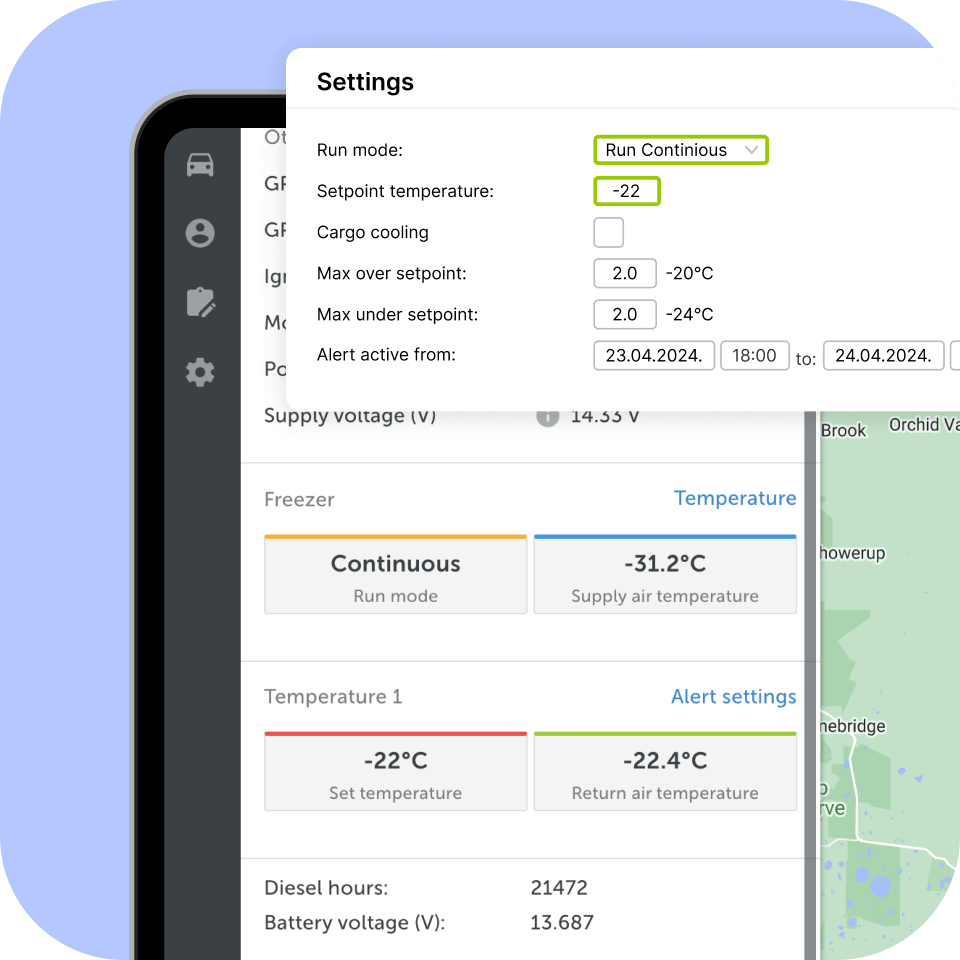

Setpoint Temperature

Supply & Return Air Temperature

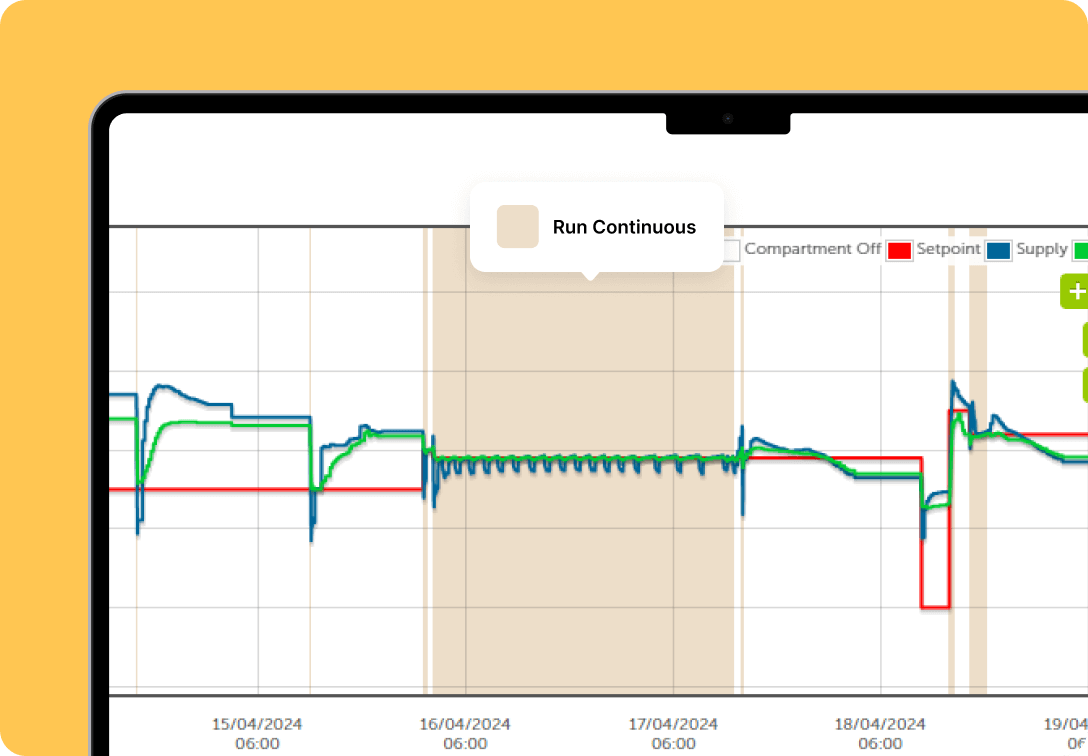

Operating Mode

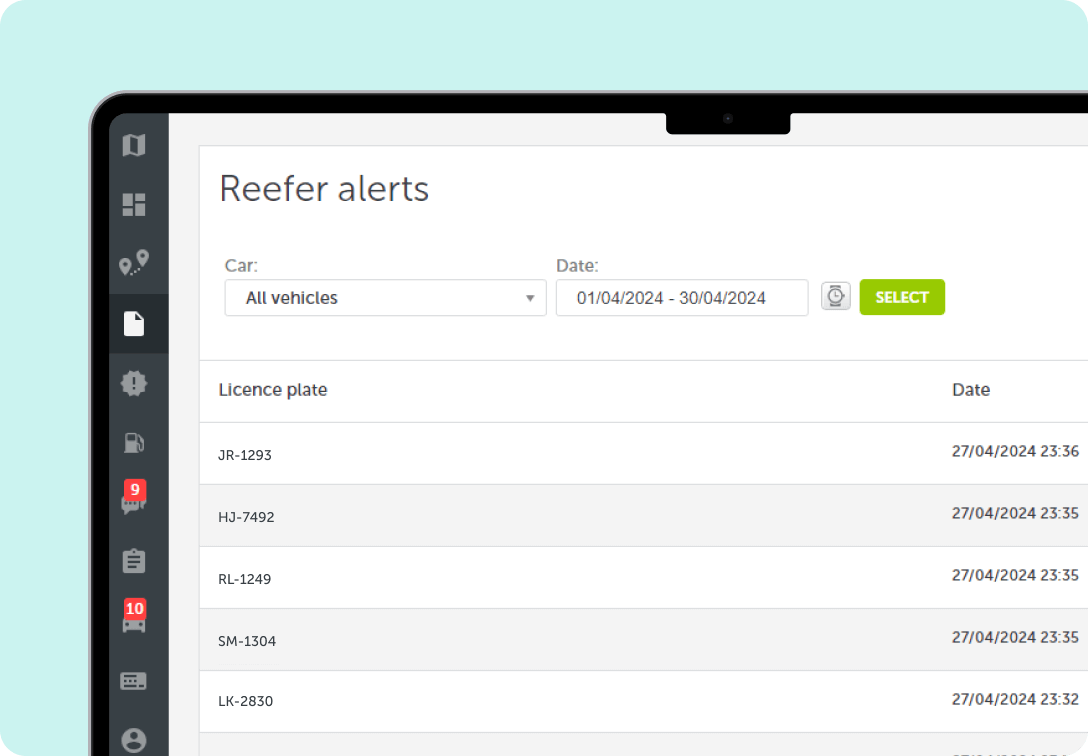

Alerts

This metric serves as a reference point for all reports and alerts. You can integrate reefer parameters with your internal shipment system to oversee the correct temperatures for every cargo.

Monitor the cooled air flowing from the reefer unit and the return air that represents the actual temperature of the product. This data helps maintain cargo integrity throughout the journey.

See whether the cargo is being transported in the continuous or start-stop mode. If the driver has chosen the wrong mode, the fleet manager receives an alert.

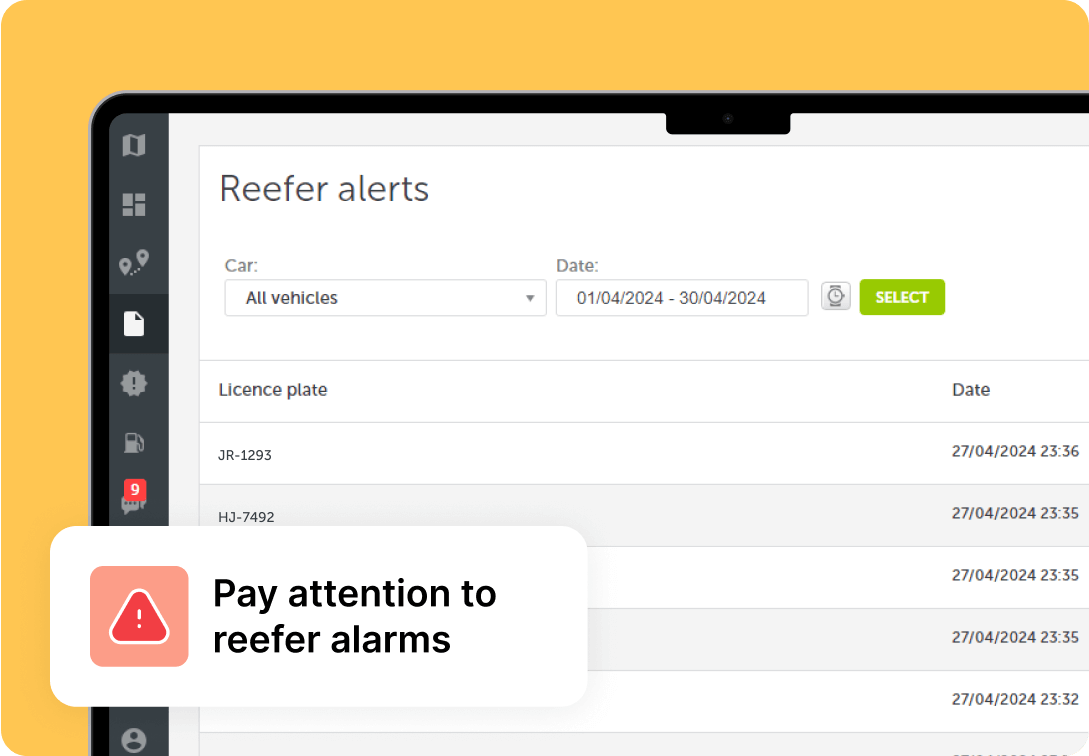

Cold chain monitoring lets you set up a range of alerts. Use them to know if the temperature or operation mode is wrong and if the cargo needs to be cooled down.

Successful cold chain tracking depends on making data-based decisions. Read our blog article to learn how to read temperature graphs and spot alarming situations!

Read more

Kreiss, an important logistics provider in the European market, has gained a clear competitive advantage thanks to the Mapon remote reefer data retrieval and integration project.

Kreiss also managed to automate many internal processes for reefer unit maintenance and cold chain monitoring, setting new standards for refrigerated product shipping companies.

Prompt Notifications

Seamless Maintenance

Cargo Cooling Procedure

Battery Updates

If anything happens to the reefer during the trip, it might take hours for the driver to notice it. A remote cold storage temperature monitoring system lets you quickly know that you need to contact the driver.

Receive timely notifications with information about refrigeration units, errors, shutdowns, necessary maintenance tasks, etc. Plan maintenance operations and find the closest service centre on the map in case of urgent issues.

If the cargo has been loaded warm, the Mapon system uses a built-in mechanism that alerts you to gradually lower the temperature to cool down the cargo without damaging it.

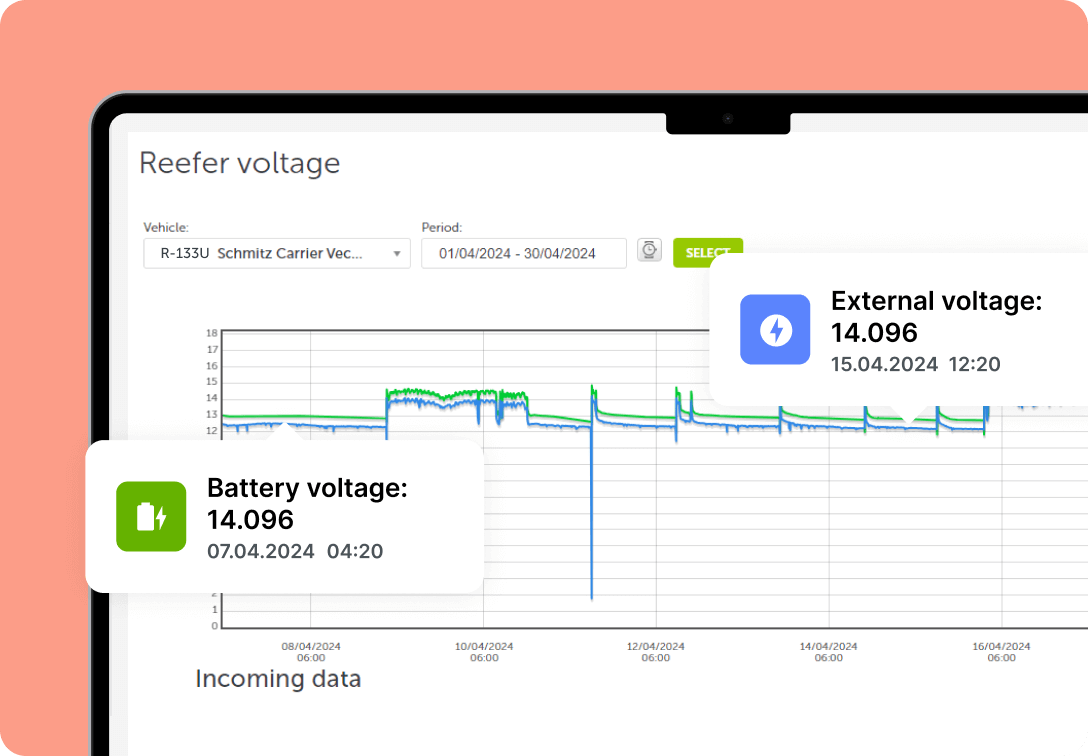

With Mapon Expert tracking devices, you can easily access refrigeration unit battery status and voltage data. Use this information to prevent battery drainage during extended periods of inactivity and save money on replacements.

With Mapon, you can also track fuel consumption and costs of Carrier and Thermo King units.

Reefer units show how many hours they operated in different power modes (diesel, electric, etc.), so you can easily calculate fuel consumption and costs.

Use our API integration feature to send the refrigeration unit data and all the important alert information to your business systems, for example, internal order management software.

Once you receive atemperature deviation alert via the API integration, you can immediately contact the driver, notify the customer of potential delays, or arrange a replacement shipment.

Implement cold chain monitoring to protect cargo and minimise losses!